Give us a call to learn more 1-888-797-3736

Global Materials products are proudly made in the U.S.A.

The Story of

Cured-In-Place-Pipe Lining

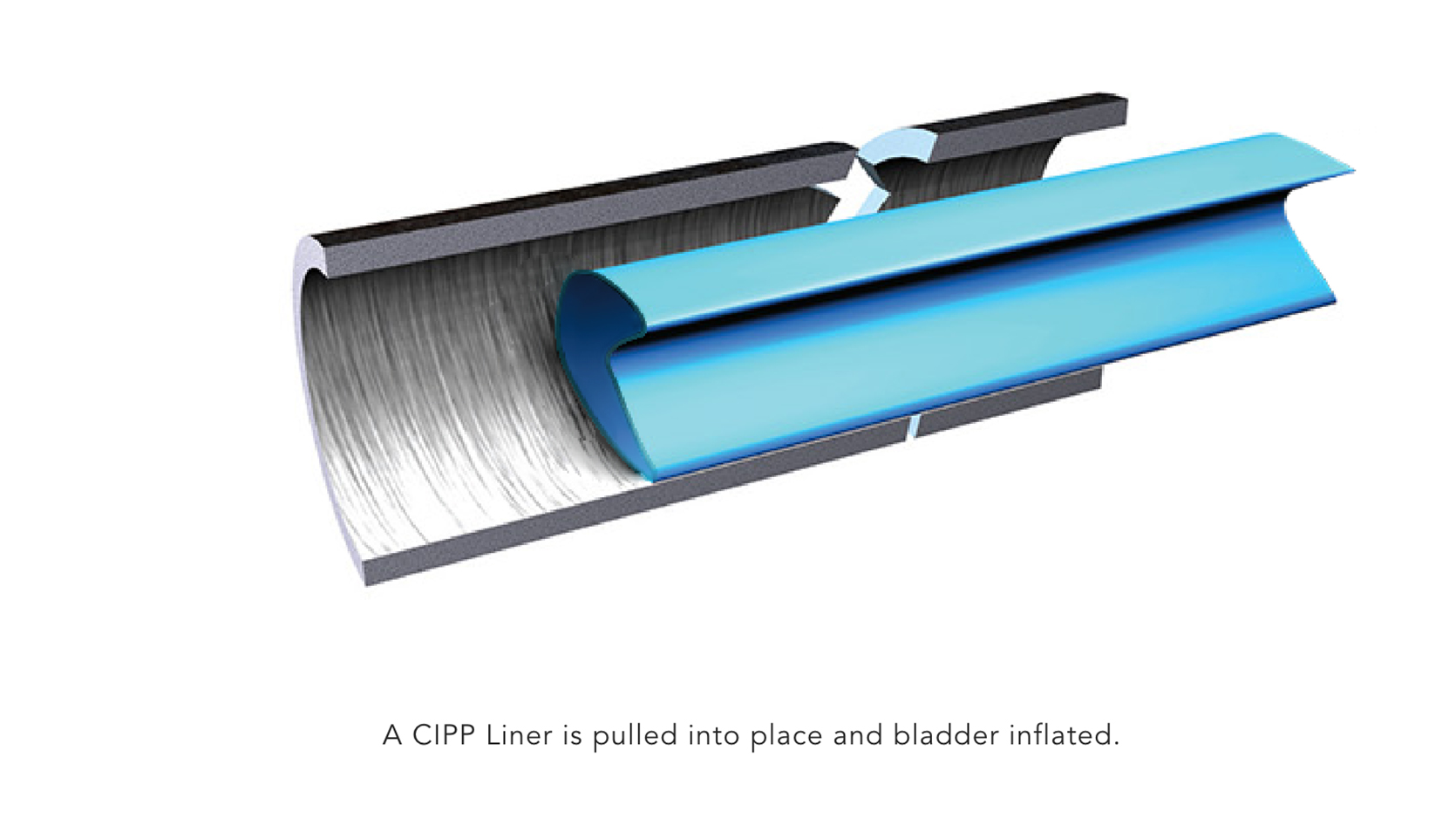

The start of CIPP began in 1971 when Eric Wood, an agricultural engineer from South Yorkshire England, experimented ways to repair the leaky pipe under his home. His goal was to repair the pipe without having to dig up his garage floor, which is what led to the development Cured-In-Place-Pipe lining (CIPP). This CIPP process involved pulling a felt tube wrapped in a plastic sheet that was impregnated with polyester resin through the leaky pipe. Wood then inflated the pipe with air and let it cure. As a result, a new hardened pipe formed inside the host pipe and the leaking issues were resolved. Wood named this process insit u form (meaning “form in place” in Latin), and was eventually granted a patent for Cured-In-Place-Pipe lining (CIPP) on February 22, 1977.

EXPLAINING

CURED-IN-PLACE-PIPE LINING

CIPP process involved pulling a felt tube wrapped in a plastic sheet that was impregnated with polyester resin through the leaky pipe. Wood then inflated the pipe with air and let it cure. As a result, a new hardened pipe formed inside the host pipe and the leaking issues were resolved. Wood named this process insit u form (meaning “form in place” in Latin), and was eventually granted a patent for Cured-In-Place-Pipe lining (CIPP) on February 22, 1977.

Ready to place an order?

No More Digging

REHABILITATE YOUR UNDERGROUND PIPELINE

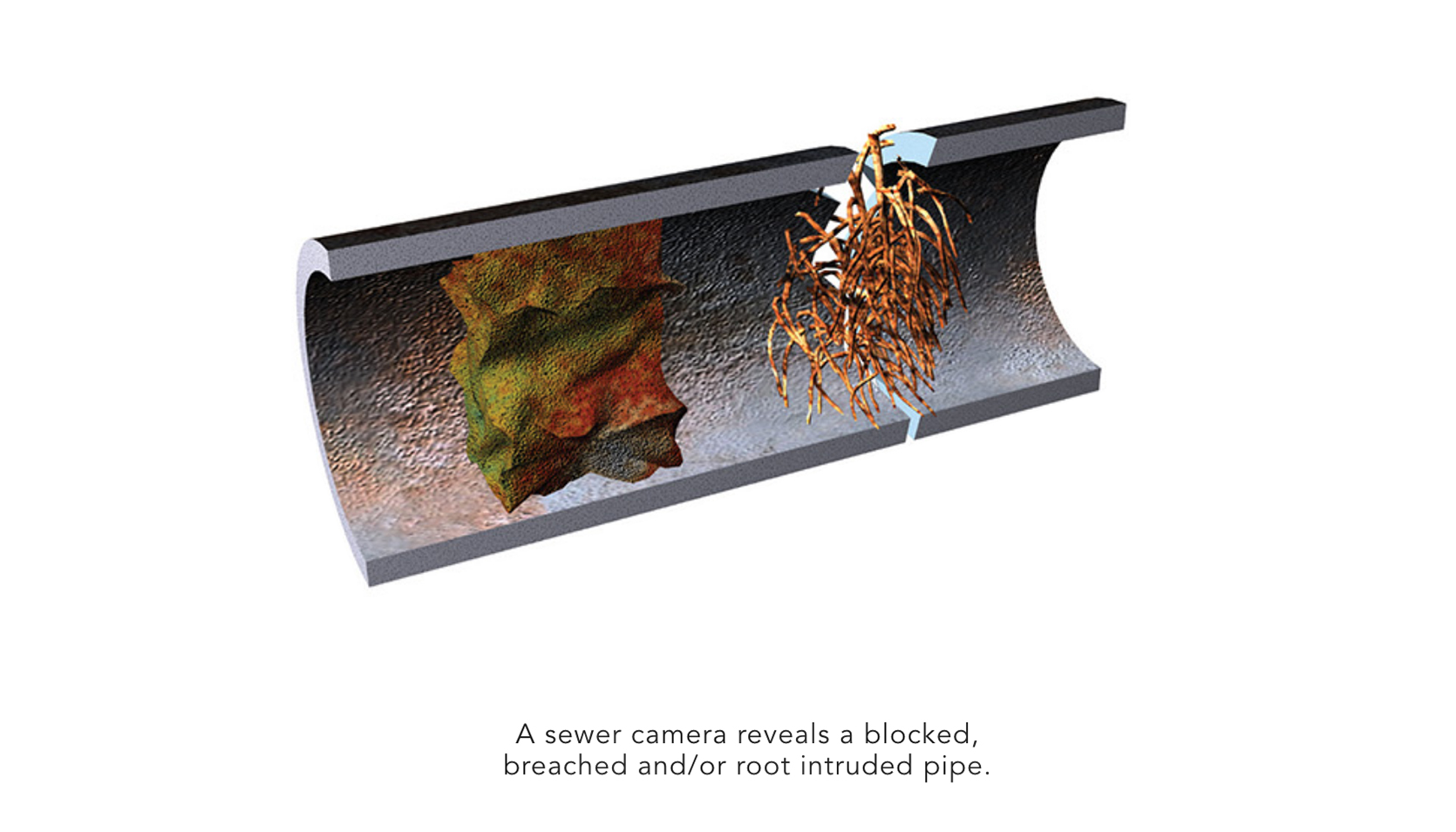

A broken or failed sewer line does not mean you have to dig it up to repair it. We can help you repair underground pipelines

without the need for excavation saving your lawn, your time and money!

How is Cured-In-Place-Pipe Lining

(CIPP) used today?

CIPP lining is an advanced trenchless repair method for compromised water, storm and sewer pipelines. The process begins with a non-woven fabric, such as felt or fiberglass cloth, that is manufactured to form a flexible tube, engineered from the specifications of the damaged host pipe. This tube then goes through the wet-out process, which is designed to impregnate the tube with resin material to create the CIPP liner. After completion of the wet-out process, the liner is inverted and pulled through the host pipe, most commonly through the upstream access point (manhole or storm drain), so that the resin coating adheres to the inside walls of the host pipe. To complete the process, the liner is hardened and cured by hot water, ambient/steam or UV light. The end result leaves you with a new jointless, seamless pipe that creates maximum flow and provides you with an extended life expectancy of 50+ years.

What are the benefits of

CIPP Lining?

The greatest benefit of CIPP lining is saving time. CIPP lining is a quicker, more cost-effective and less disruptive pipe rehabilitation method, compared to the “dig and replace” method, since it does not require a lot of digging, excessive heavy equipment or a large crew. With modern technology, pipelining allows you to complete these projects with smaller crews, as well as less costs and downtime associated with permitting, restoration, extensive road closures and so much more. The length of the lining process ultimately depends on the complexity of the project, but in most cases, it is a quick fix. The more time you save, the more money you save.

The greatest benefit of CIPP lining is saving time. CIPP lining is a quicker, more cost-effective and less disruptive pipe rehabilitation method, compared to the “dig and replace” method, since it does not require a lot of digging, excessive heavy equipment or a large crew. With modern technology, pipelining allows you to complete these projects with smaller crews, as well as less costs and downtime associated with permitting, restoration, extensive road closures and so much more. The length of the lining process ultimately depends on the complexity of the project, but in most cases, it is a quick fix. The more time you save, the more money you save.

CONTACT INFORMATION

1-888-797-3736

© 2022 Global Materials | All rights reserved | Site by ACGD

© 2022 Global Materials | All rights reserved | Site by ACGD